Aprende en Comunidad

Avalados por :

¡Acceso SAP S/4HANA desde $100!

Acceso a SAPLa importancia de la trazabilidad de materiales en la cadena de suministro: beneficios y desafíos.

- Creado 01/03/2024

- Modificado 01/03/2024

- 96 Vistas

When the phrase "material traceability" comes up in industry or academia, it is often accompanied by words like "provenance" and "genealogy". But what does that all mean to the people closest to this topic: producers, processors, retailers… and most importantly consumers?

To avoid uncommon descriptors related to material traceability, the people who care about material traceability can sum it up in three questions:

- Where did my stuff come from?

- What’s in the stuff I received?

- Where did my stuff go when I used / shipped it?

Material traceability is the process of ensuring that the raw materials or components of a product have a record of origin, production, and destination or consumption to support traceback or recall analysis after receipt, production, or distribution. Material traceability is an essential part of supply chain analytics playing a critical role in quality, manufacturing and planning, legal and compliance, brand management, and sustainability functions, among others.

Why is material Traceability important?As the process of capturing information to know the origin of the elements of a product, the composition of that product, and distribution or end-use of that product, material traceability most commonly results in product stewardship benefits to safety, sustainability, and product design. Material traceability enables the transparency needed for supply chain accountability to support safety, quality, compliance, and brand integrity. Accurate and efficient material or product traceability is essential in food and beverage, agriculture, consumer packaged goods, life sciences, and regulated industries, among others.

Where does material traceability information come from?Material traceability origin and product attribute data can come from suppliers at every level of a supply chain, sufficient to meet a manufacturer's or brand owner's requirements and objectives. Critical material and product traceability data can also come from the manufacturer and its distribution and retail partners, as well as customers and consumers, for full end-to-end traceability.

What are the benefits of material traceability?Material traceability enables faster and more accurate recalls and tracebacks when quality or safety issues arise. Manufacturers and brand owners are able to meet compliance and brand integrity requirements more efficiently and demonstrate product stewardship and authenticity more accurately. The benefits of material traceability enhance the effectiveness of quality, compliance sustainability, and supply chain analytics functions of a business.

What are the challenges to achieve efficient and effective material traceability?The desire to trace the things we use and consume has been around even long before safety regulations were put in place, but the challenge has always been around how to make this process accurate, efficient and effective to reach its objectives. Material traceability has long been a paper chase, through purchase, orders, bills of lading, and evidence of good receipt. Assuming the documentation itself can be validated, let alone the good that the paperwork pertains to, the vast volume of growing economies has made the material traceability paper chase in need for an automation solution.

But a process automation solution for material traceability is challenged further by the need to span organizations across a supply chain to capture the information needed for effective tracing and product recalls when needed.

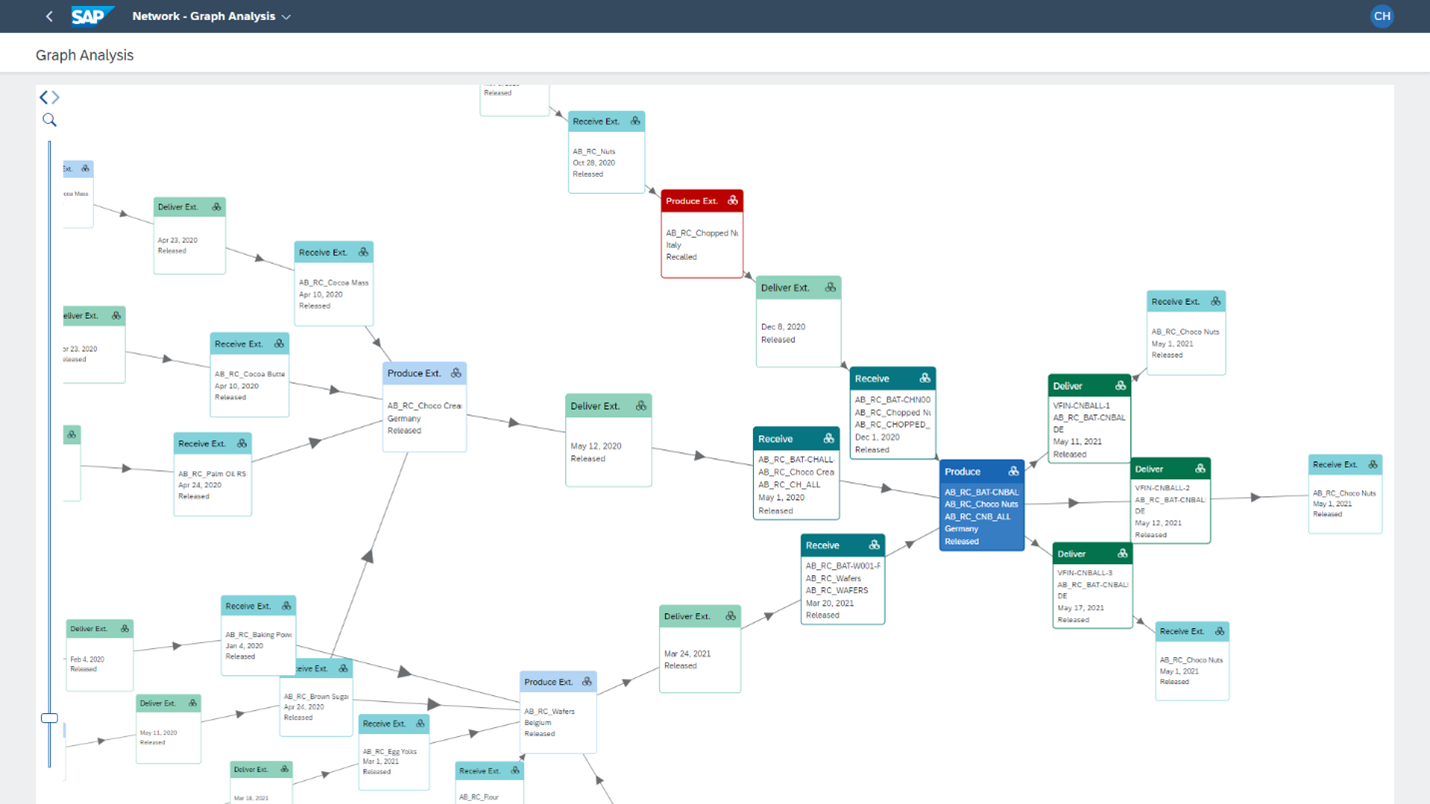

What does the SAP Business Network Material Traceability solution do?SAP Business Network Material Traceability captures event and attribute data for batch or serialized products from trading partners, enabling bidirectional tracing through a graphical visualization showing the digital trail of inputs and outputs. The solution enables precise, efficient recalls and tracebacks, along with alerts, extensible attributes for sustainability or other product composition analysis, and native reporting that can be extended and integrated through APIs.

SAP Business Network Material Traceability captures event and attribute data for batch or serialized products from trading partners, enabling bidirectional tracing through a graphical visualization showing the digital trail of inputs and outputs.

SAP Business Network Material Traceability allows you to capture complete material provenance from raw material to finished product, whether tracing batch or serial numbers across your value chain. With this solution, businesses can improve efficiency, enhance trust, and improve sustainability by extending supply chain transparency.

Learn more about SAP Business Network Material Traceability from the solution brief here, and stay tuned for future posts to help put the process of material traceability into context for your business.

Sin respuestas

No hay respuestas para mostrar

Se el primero en responder

No hay respuestas para mostrar

Se el primero en responder

© 2025 Copyright. Todos los derechos reservados.

Desarrollado por Prime Institute